Double Side Panel Cleaning System is our auxiliary machine produced for removing dust, sawdust and etc. may remain on the product just before the painting process after the sanding process. We recommend using dusting unit before painting for smooth painted surfaces.

Elite Woodworking Machinery

About

If you would like more information, please contact us using the form below.

Click to view our full range of New Woodworking Machinery.

Click to view our full range of Used Woodworking Machinery.

Check us out on Facebook!

APPLICATION AREAS

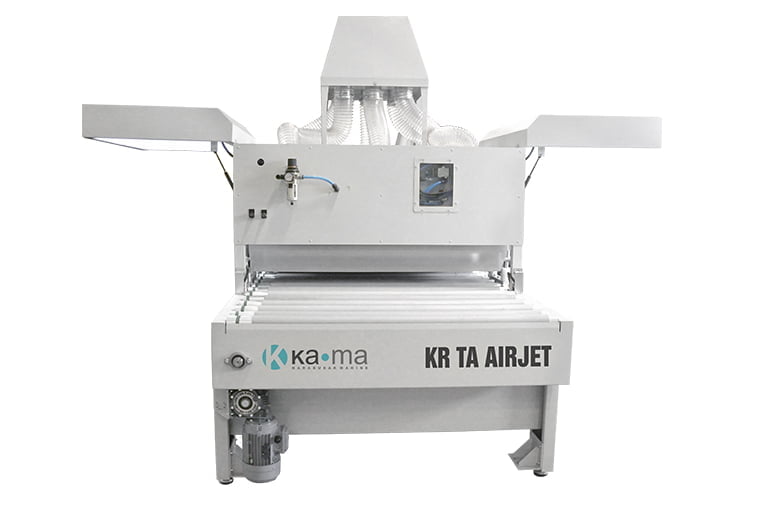

DOUBLE SIDE PANEL CLEANING SYSTEM

Double Side Panel Cleaning System is our auxiliary machine produced for removing dust, sawdust and etc. may remain on the product just before the painting process after the sanding process. We recommend using dusting unit before painting for smooth painted surfaces.

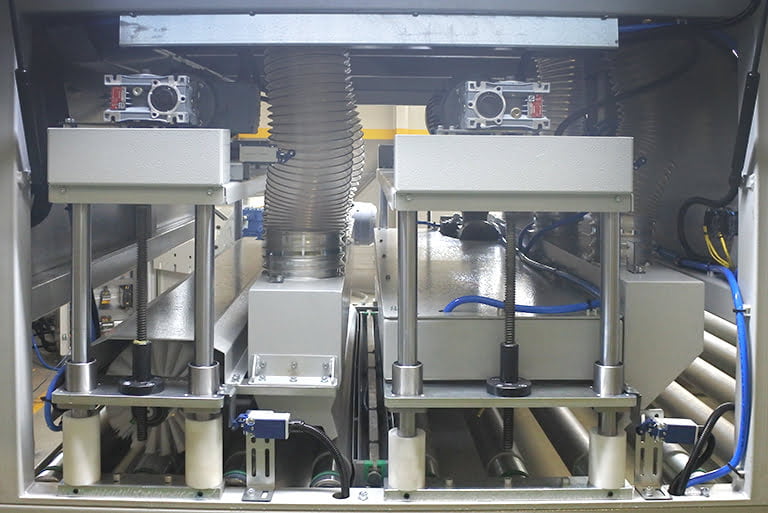

Our dusting unit, which is installed right after our automatic sanding machines and enables the removal of dust, sawdust and etc. remaining on the product to be processed according to need, eliminates the static electricity on the product thanks to its antistatic feature. The Double Side Panel Cleaning System, which enables its users to get the best results on the surfaces, allows the sanded product to be painted smoothly. The paint sprayed on the products that are free of dust and antistatic electricity adheres better to the surface and allows a smooth painting.

Unlike traditional methods, the dusting unit is an auxiliary equipment that saves energy and makes it easier to get quality results.

All dust particles that may remain on the product are cleaned thanks to the 16 air nozzles, dust collecting brushes and height adjustment in the Dusting Unit,. In addition, its moving air curtain cleans the bottom surface of the product and makes it ready for painting. Conveyor speed is frequency controlled.

Double Side Panel Cleaning Systemis offered as standard feature in our KR BM 1700 Automatic Spraying Machine.

IoT

In this system, all kind of data about working and defects on machine is recorded momentarily on the all KAMA machines so that it helps to its user using the gained informations. So you can see momentarily the working status of your machine and get information about the defects experienced. You can check who worked how long and production volume during operation and past reports with details. You can get specific reports when you filter the parameters on data given. Furthermore by setting up the different type of alarms you can perform your work status without problem.

REMOTE TECHNICAL SUPPORT SYSTEM WITH INCREASED REALITY

With the Vsight Remote application, which we offer our remote technical service much more quickly and practically, we greatly prevent the downtime that may occur during the use of our machines. Your machine operator can instantly connect to the technical service officer at the KAMA headquarters with a smartphone, tablet or smart glasses. In this way, the necessary intervention can be made within seconds with voice and video call problem malfunctions, marking and voice commands on live video.

STANDARD FEATURES

Airjet Blower

Brush Cleaner

Anti Static Bar

Oscillatory Blowing Bar

Motorized Roller Conveyor

OPTIONAL FEATURES

Bottom Surface Brush

TECHNICAL SPECIFICATION

Length: 2.300 mm

Width: 2.200 mm

Height: 1.900 mm

Airjet Blower with Double Nozlles: 8 Pcs

Total Electrical Demand: 3.5 kW/h

Compressed Air Consumption: 1000 lt/min

Dust Collector Capacity: 10.000 m3/h

Watch Now Double Side Panel Cleaning System

Find out more

Elite Woodworking Machinery

01 699 1516

info@elitewoodworkingmachinery.ie

Address

Clonee, Dublin 15.